How did the WPM CRACK INDUCER profile get started?

The WPM CRACK INDUCER profile was created in 2018 when the CEO Indrek Uusalu decided to start producing the construction joint profiles in Estonia. Being involved in the daily work of Primostar OÜ’s by selling waterproofing products and seeing construction works in Traveter Ehitus OÜ gave a very clear understanding of the market situation. Having used a crystalline admixture to make concrete waterproof for 10 years, the bottlenecks in this system had emerged. Indrek saw that he could solve them.

Thus in August 2018 WPMEstonia OÜ was created to manufacture waterproofing solutions for concrete structure construction joints and controlled cracks. The answer for the bottlenecks was a pin-shaped WPM CRACK INDUCER profile.

What is WPM CRACK INDUCER profile?

The WPM CRACK INDUCER profile is part of a three-part waterproofing solution or “white tank” method. The profile is designed to work with other WPM construction joint profiles and crystalline admixture.

By its nature, the WPM CRACK INDUCER profile creates a pin-shaped crack in the concrete structure when it adheres tightly to the concrete. Perpendicular to it is a perforated steel sheet with a mineral coating that makes the resulting shrinkage crack waterproof and thus prevents water from penetrating the building. The purpose of the pin-shaped crack is to maintain the strength of the structure so we can use the profile in load-bearing structures.

What is the purpose of the profile?

The purpose of the profile is to simplify the waterproofing of reinforced concrete structures and speed up the concrete casting process. While concrete structures are usually poured in stages to minimize the shrinkage of the concrete during drying, using the WPM CRACK INDUCER profile, we can control where the shrinkage cracks appear and waterproof it at the same time.

How to install WPM CRACK INDUCER profile in concrete construction?

The profile is installed between the wall, ceiling, and floor reinforcements rebars. The calculator calculates the installation distance between the profiles by taking into account the shrinkage of the concrete. This means that the distances between the profiles are exactly so large that no additional crack would form between them due to shrinkage.

How does the WPM CRACK INDUCER profile ensure the water tightness of a concrete structure?

When hardening, the concrete shrinks, creating cracks in the structure. With the help of calculations, we can determine where the WPM CRACK INDUCER profile would be most sensible to install to control the shrinkage cracks and waterproof them. The profile waterproofs the concrete structure by a steel sheet with a mineral coating perpendicular to the pin-shaped crack created by the profile. The steel sheet acts as an obstacle when perpendicular to the pin-shaped crack.

How to pour more concrete with less time by using WPM CRACK INDUCER profile?

As we know, concrete is a material that shrinks as it hardens, so it is necessary to consider this when constructing the structure. We can reduce the shrinkage by adding more reinforcement rebars to the concrete. In principle, if desired, it is possible to pour the concrete with a more considerable amount of reinforcement than usual without shrinkage. This means that if the amount of iron in the structure is such that the tensile strength of the reinforcement exceeds the tensile strength of the concrete, no shrinkage cracks will occur. However, this would raise the construction cost unreasonably high, and this approach is generally not used.

This is where the efficiency of the WPM CRACK INDUCER profile comes in. It allows you to keep the amount of reinforcement in the design reasonable and enable the profile to create controlled cracks exactly where we want them.

Because the profile allows us to control shrinkage cracks and make them waterproof, we don’t have to worry about accidental cracks when pouring large amounts of concrete at once. In this way, after the concrete has hardened, we can pour all the walls simultaneously. The same applies to the basement ceilings.

However, we would like to point out that the pouring pipe has to be as low as possible at the bottom of the formwork when pouring concrete into the formwork. In that way, it does not separate the concrete mixture into larger and smaller parts of the concrete if it falls to the base against the edge of the reinforcement. In this case, larger pieces usually fall to the bottom of the floor before and do not allow to form a dense concrete form around the construction joint profile or WPM CRACK INDUCER profile. This, in turn, is likely to cause water to seep through the structure. We have seen this problem times and times again over the years and have eliminated the consequences. From experience, we can make recommendations to help you avoid these costly mistakes.

We are aware of the routines of how concrete is poured. Still, in our opinion, a well-thought-out, careful, and perhaps a little more timely casting process outweighs the leaking structure, which must be re-waterproofed with additional resources later.

On which projects have we used the WPM CRACK INDUCER profile?

We have used WPM CRACK INDUCER profile on the following sites:

In Estonia

- Kiikri 6, Tallinn

- TÜ Kliinikumi juurdeehitus, Tartu

- Taime 6, Tallinn

- Tammsaare 86, Tallinn

- Valge 16, Tallinn

In Latvia: - Tērbatas iela 72, Riga

- Rūpniecības iela 27, Riga

- Marijas iela 2a, Riga

- Lauku iela 23, Riga

In Lithuania: - Manufaktūrų g. 7, Vilnius.

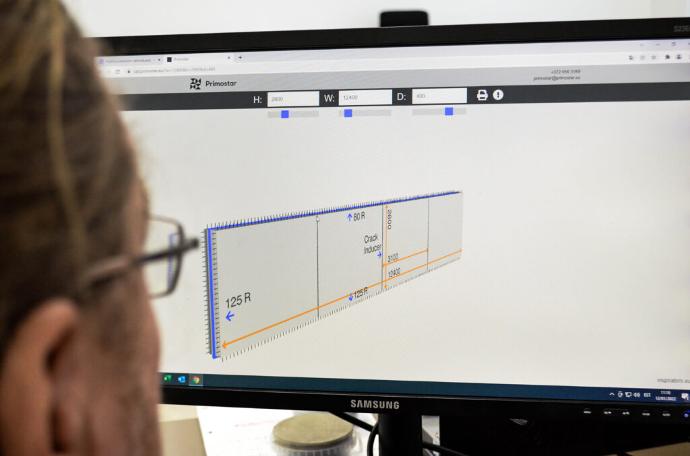

3D Automatic Crack Inducer Calculator

To make installing profiles even easier, we decided to create a 3D Automatic Crack Inducer Calculator. The calculator calculates the amount of WPM CRACK INDUCER profile required for the design and the exact installation locations. The calculator also shows all other construction joint profiles and their installation locations. Only the thickness, height, and length of the structure are needed for the calculator’s input. Then a 3D drawing of the structure is automatically rendered, which can be viewed 360 °. Also, the 2D plan can be printed out with the legend of the quantities of the profiles.

In conclusion

The WPM CRACK INDUCER profile has 2 objectives:

- waterproof shrinkage cracks

- control shrinkage cracks to pour more concrete and save time spent on the process

A small calculation shows that using the WPM CRACK INDUCER profile in concrete structures’ casting and waterproofing processes offers a significant advantage in terms of financial and time savings. The profile helps to reduce waterproofing costs by more than half compared to the rolling membrane or roll-on waterproofing materials.

Calculations with material and working hours:

| Waterproofing with a membrane (black tank method)

|

Waterproofing with crystalline admixture and WPM profiles (white tank method)

|

|

Foundation

| 3200m2 x 35€ = 112 000€ | 1000m3 x 3kg = 3000kg x 6.90€ = 20 700€ |

| Walls | 1700m2 x 22€ = 37 400€ |

425 м3 × 3 кг = 1275 кг × 6,90 € = 8 797,5 €

|

|

Ceiling (-1)

| 3200m2 x 20€ = 64 000€ | 1000m3 x 3kg = 3000kg x 6.90€ = 20 700€ |

|

Ceiling (0) | 3200m2 x 20€ = 64 000€ | 1000m3 x 3kg = 3000kg x 6.90€ = 20 700€ |

|

WPM CRACK INDUCER

| – | 660m x 51.50€ = 33 990€ |

|

WPM SEALING ELEMENT

| 500m x 10€ = 5000€ | 500m x 10€ = 5000€ |

|

Armature/reinforcement

| 1000m x 10€ = 10 000€ | 1000m x 10€ = 10 000€ |

|

Sum

| 292 400€ | 119 887.5€ |

If a crack occurs in the structure that opens less than 0.4mm, does not grow together with crystals, and leaks water, we will inject it at our own expense.

WPM CRACK INDUCER profile is a product developed by WPMEstonia OÜ, which is currently being patented.

If you want to know if and how we can make your concrete structures waterproof and speed up the casting process with the “white tank” method, then contact us, and we will review the project together.