How We Optimize Your Below-Grade Waterproofing Solution Up to 10X Greener?

Tested in Lab and Real-life Projects

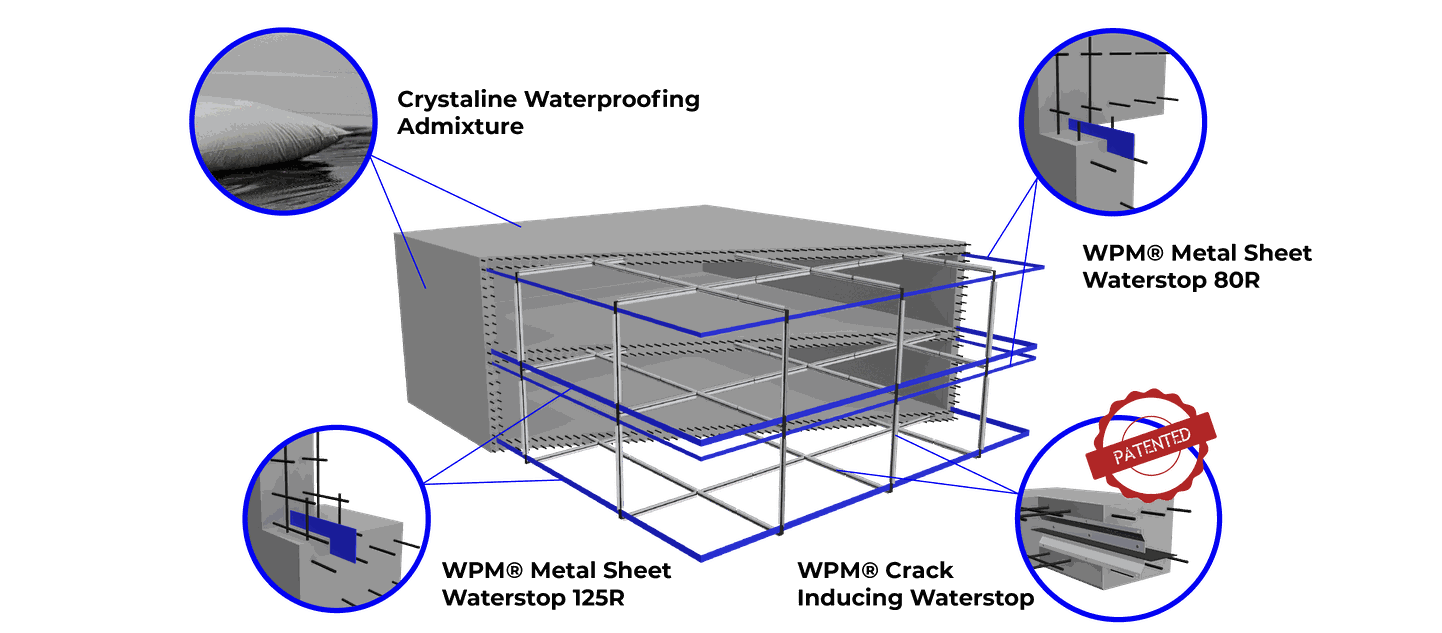

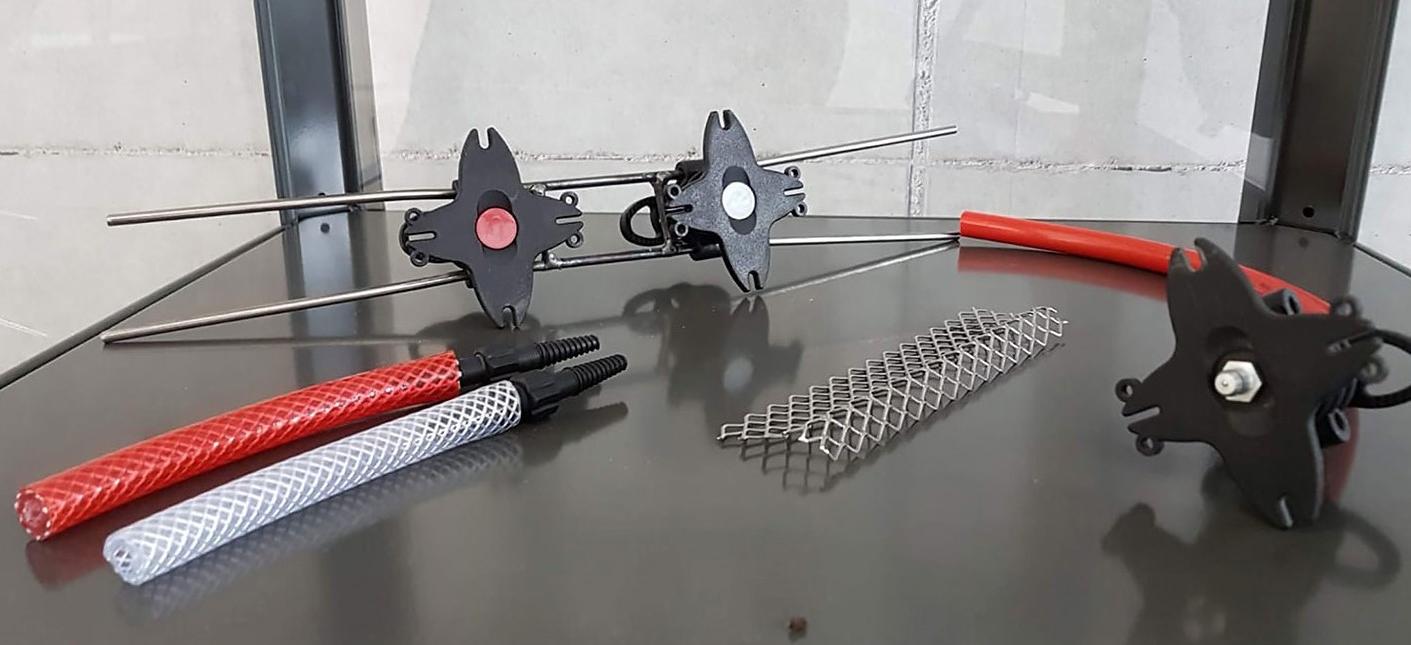

3 COMPONENT SOLUTION

to control and waterproof leaking shrinkage cracks!

WPM® Crack Inducing Waterstop

For controlling and waterproofing concrete shrinkage cracks

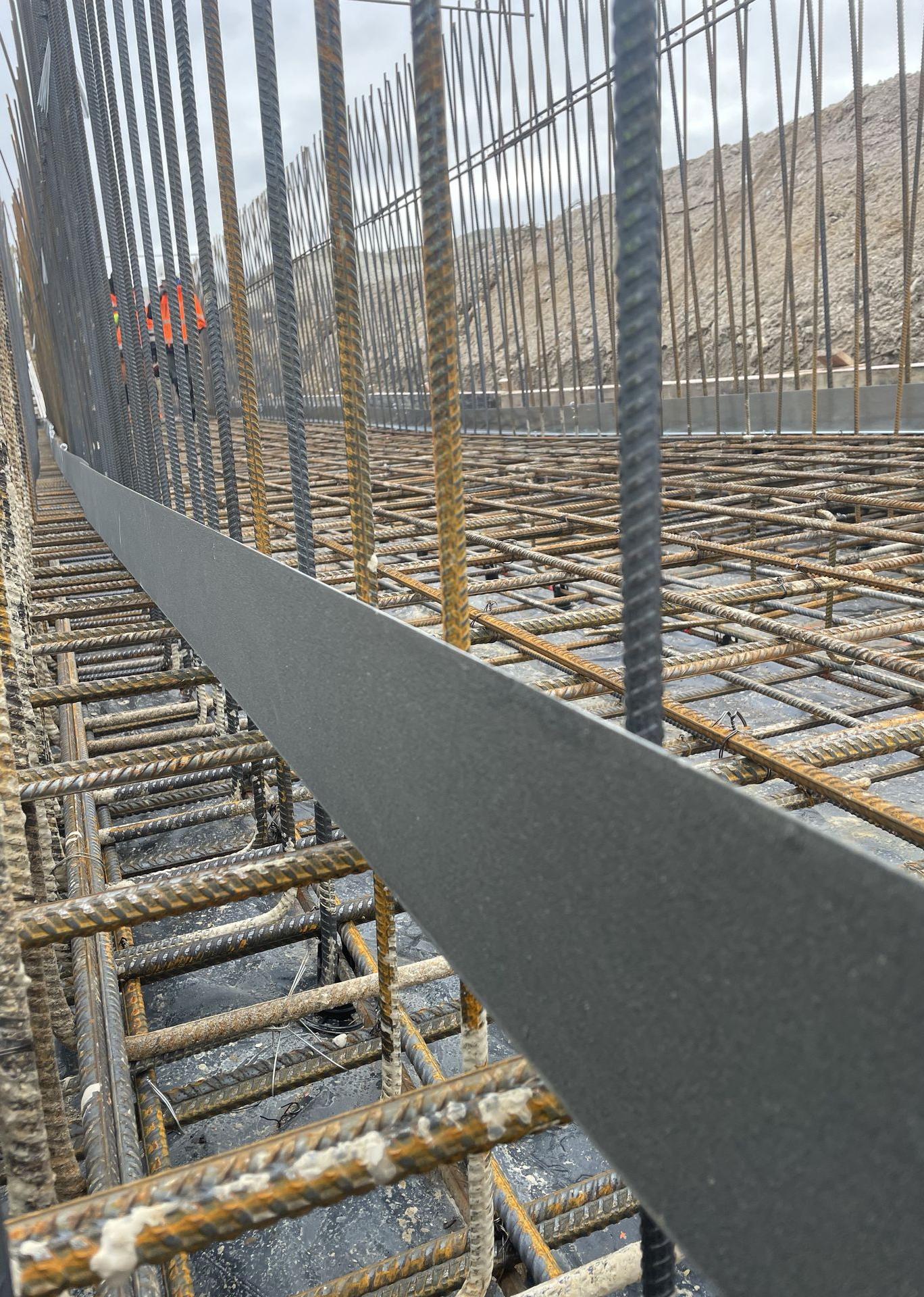

WPM® Metal sheet Waterstop

To waterproof construction joints up to 2.4 bar positive waterpressure

Crystalline admixture

Gives concrete

“self-healing”

ability for cracks up to 0.4 mm.

INTEGRAL, I.E., WHITE TANK WATERPROOFING SOLUTION

helps you

Save environment

You will use 2-10x less waterproofing materials which reduces the ecological footprint

Save installation time

You can install material quicker = have fewer labor costs, do more jobs, and help more customers.

Save money

You will save money on labour and material costs.

UP TO 10X GREENER?

Waterproofing Solutions Materials Consumptions Comparison by m²

Black Tank Waterproofing

Materials used:

- 2 layers of 3mm SBS material (floor slab)

- WPM® metal sheet waterstops

- Primer

- 2 layers of 3mm SBS material (wall)

NET weight: 9.8kg/m²

Membrane Waterproofing

Materials used:

- WFP Pre-Tec

- WPM® metal sheet waterstops

- Primer

- Köster KSK

NET weight: 2.1kg/m²

Integral i.e. White TankWaterproofing

Materials used:

- Crystalline admixture 3kg/m³

- WPM® metal sheet waterstops

- WPM® Crack Inducing Waterstops

NET weight: 1.05kg/m² - Crystalline admixture 1kg/m³

- WPM® metal sheet waterstops

-

WPM® Crack Inducing Waterstops

NET weight: 0.48kg/m²

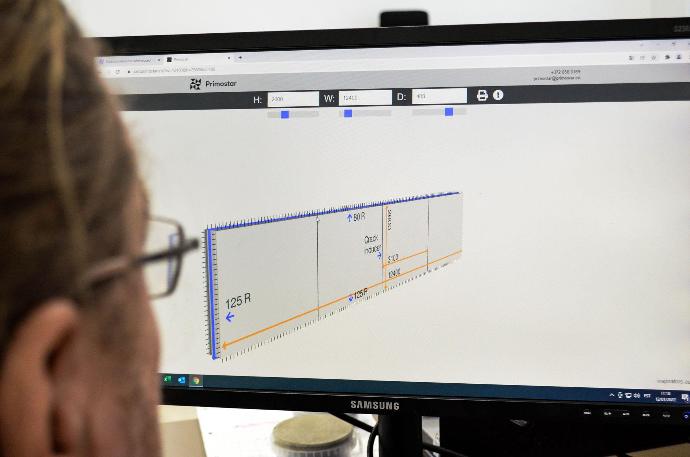

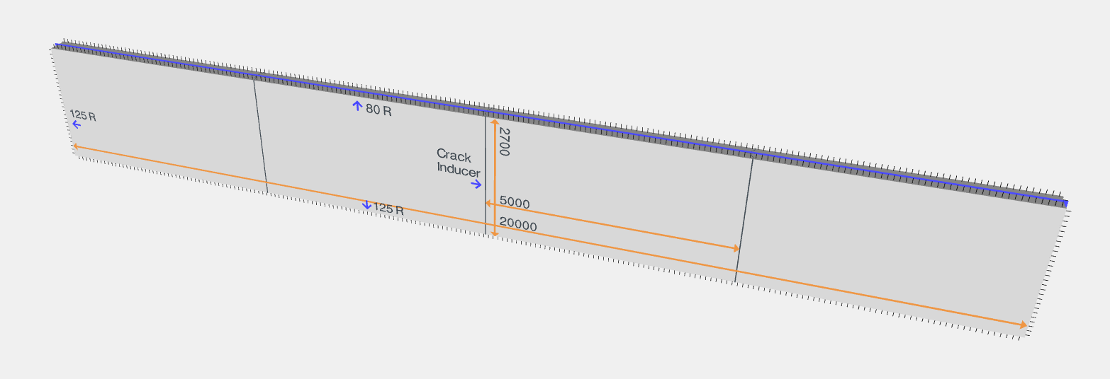

3D Automatic Crack Inducer Calculator

To make our customer's life easier, we made a 3D Automatic Crack Inducer Calculator solution, which calculates the quantity of all WPM® construction joint profiles. Just add height, length, and width. The calculator is interactive and can be viewed 360 degrees from any angle.

In addition, we are working on a next-generation calculator so we can add the whole concrete structure plan with the pipe and cable penetrations.

3D AUTOMATIC CRACK INDUCER CALCULATOR

MORE ABOUT THE MATERIALS

used in the "white tank" waterproofing system

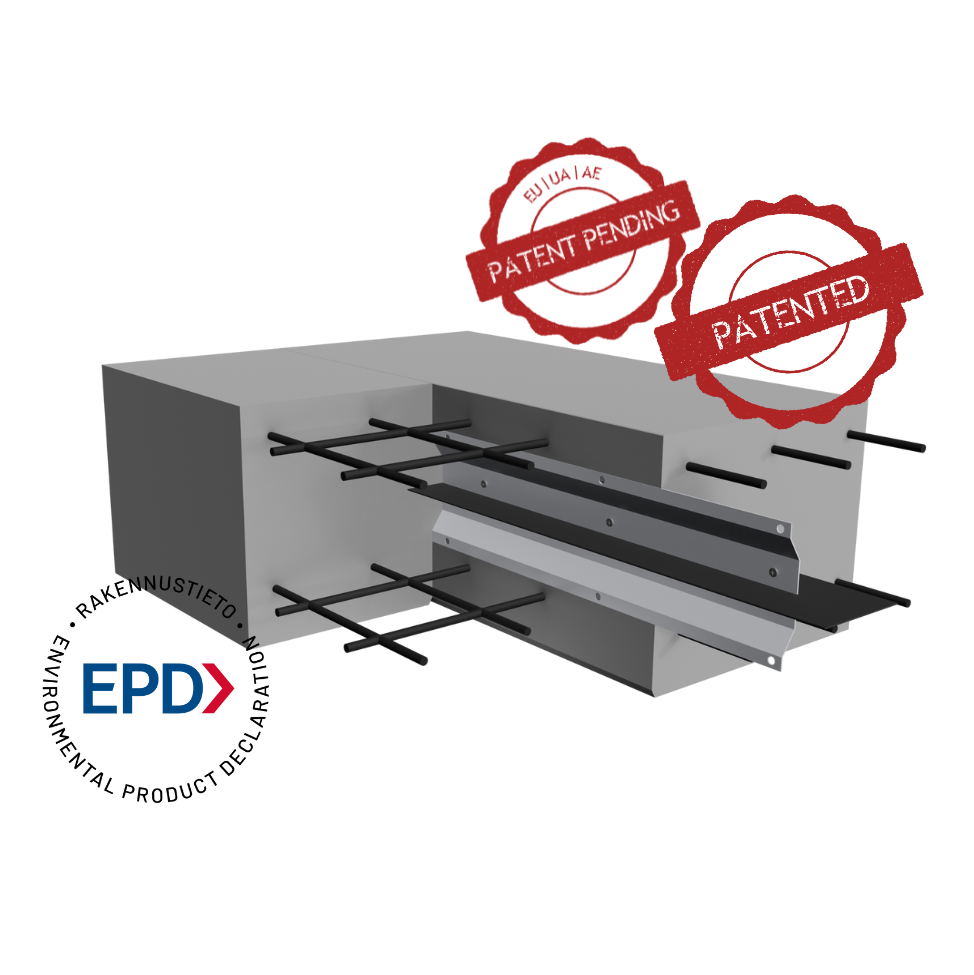

WPM® Crack Inducing Waterstop

In 2008, we started to use crystalline admixture in hopes of solving our problems with shrinkage cracks due to the fact that it can grow together to 0.4mm cracks. When engineers calculated 0.2 to 0.3mm cracks to 1m of the reinforced concrete structure in the construction design, it seemed like a perfect fit at the time.

When we understood that some cracks open more than 0.4 mm and that crystalline admixture could not grow them together, we designed a solution for controlling the shrinkage of reinforced concrete structures so that the cracks produced by the shrinkage are immediately watertight at the desired location. We added a keyway shape to the profile to make the joint connection stronger so that it can be used in load-bearing structures.

In addition, as the crystalline admixture can not grow together dynamic cracks that open and close, the WPM® CRACK INDUCING waterstop allows that movement to happen, making dynamic cracks watertight.

WPM® Metal Sheet Waterstop

WPM® METAL SHEET WATERSTOP profiles, i.e., waterstops, are designed to waterproof construction joints. Compared to alternative solutions, the metal sheet is more reliable and long-lasting. We have added polymer coating to make concrete and metal sheet connections stronger and reliable.

WPM® Waterstops works with up to 2.4 bar of positive water pressure.

Crystalline waterproofing admixture

The crystalline admixture gives the concrete a “self-healing” ability. With the water entering the crack, the admixture can close the static cracks in the concrete with an opening width of less than 0.4 mm.

When the crack is under constant dynamic load, i.e., moving constantly, the admixture can not heal shrinkage cracks. In that case, we need a solution that enables the concrete block to move and waterproof the cracks that the moving has made. For that, we made WPM® Crack Inducing waterstop.

Crystalline admixture is packaged into a soluble bag, which makes the mixing process easier and with zero waste!

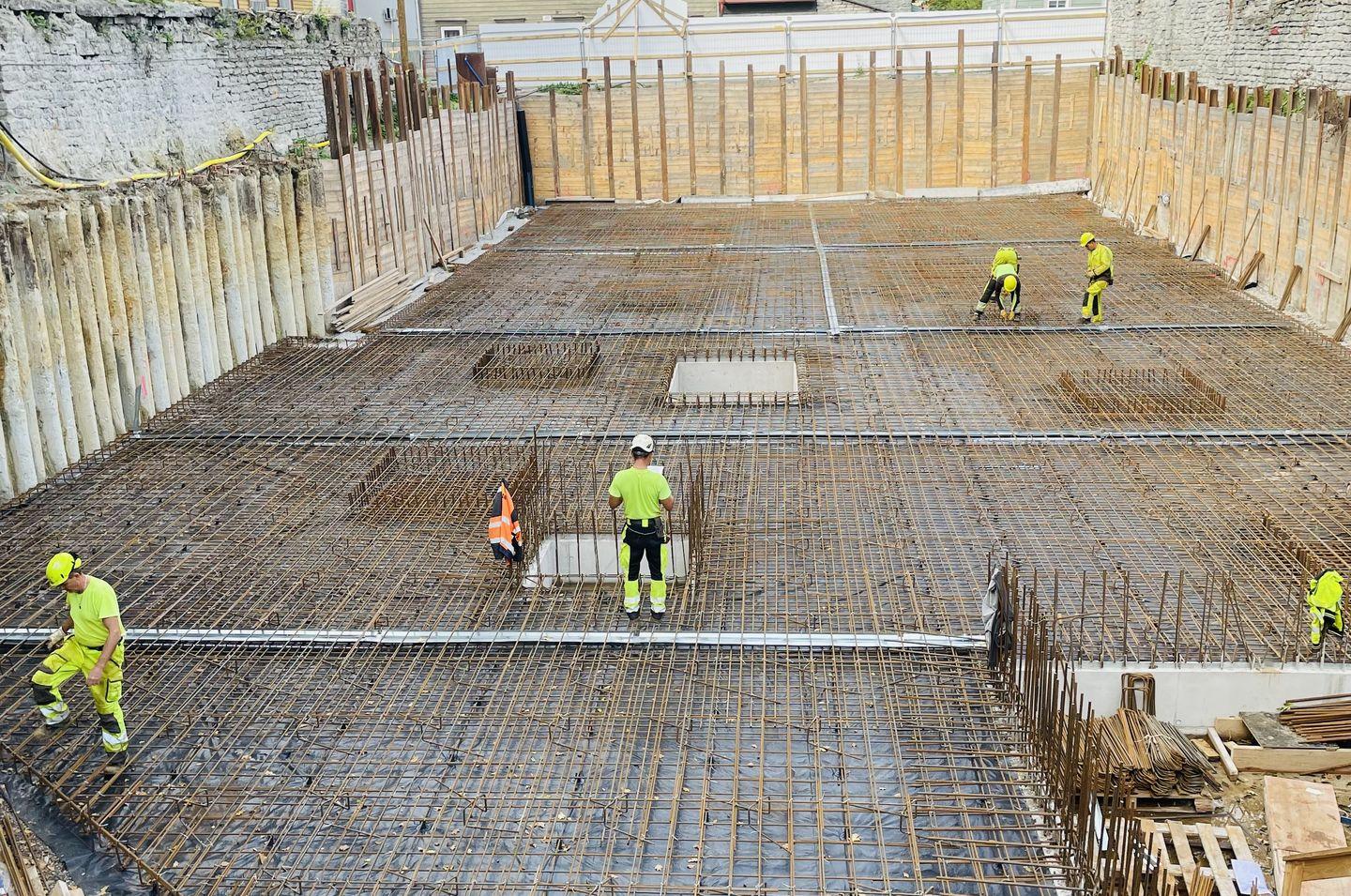

WATERPROOFING STEP-BY-STEP PROCESS

in the integral, i.e., "white tank" waterproofing system

WPM® Crack Inducing Waterstop

WPM® Crack Inducing waterstop profiles are added to the concrete structure to control shrinkage cracks.

Using our 3D Automatic Crack Inducer Calculator's plan, the instalment of the profile is easier than ever, because it shows exactly where to install the profile by a cm.

WPM®

Metal sheet Waterstop

Construction joint profiles are added just before the casting process to prevent water infiltration from the construction joints.

Using our 3D Automatic Crack Inducer Calculator's plan, the instalment of the profile is easier than ever.

Crystalline admixture to concrete mix

Crystalline admixture is mixed to the concrete in the concrete factory. We use crystalline admixture in soluble bags so it can be inserted to the mix conveniently and with no waste.

Concrete casting

Concrete that is mixed with crystalline admixture is being pored after all the construction joint profiles and crack inducing profiles are installed.

Concrete structure is waterproof after casting proccess!

There is no need to add an additional membrane to the outer layer of the structure - unless the underground part is used as living quarters.

If there will be any cracks crystalline admixture in the concrete will grow it together (cracks up to 0.4mm)

ADDITIONAL MATERIALS

we use to waterproof all extra necessary components

KRASO -

Pipe Penetrations

Kraso pipe penetrations and sealing elements, makes it easy to penetrate pipes and cables through concrete walls without water infiltration.

BeSealed -

Plugs and Rings

BeSealed hydrophilic plugs and rings allow us to waterproof concrete cracks around formwork spacers and formwork spacers themselves.

WFP Injection System

Using as a backup addition to construction joint waterstops, allows to inject injection resign to close all openings in construction joint to stop water infiltration if it were to happen.

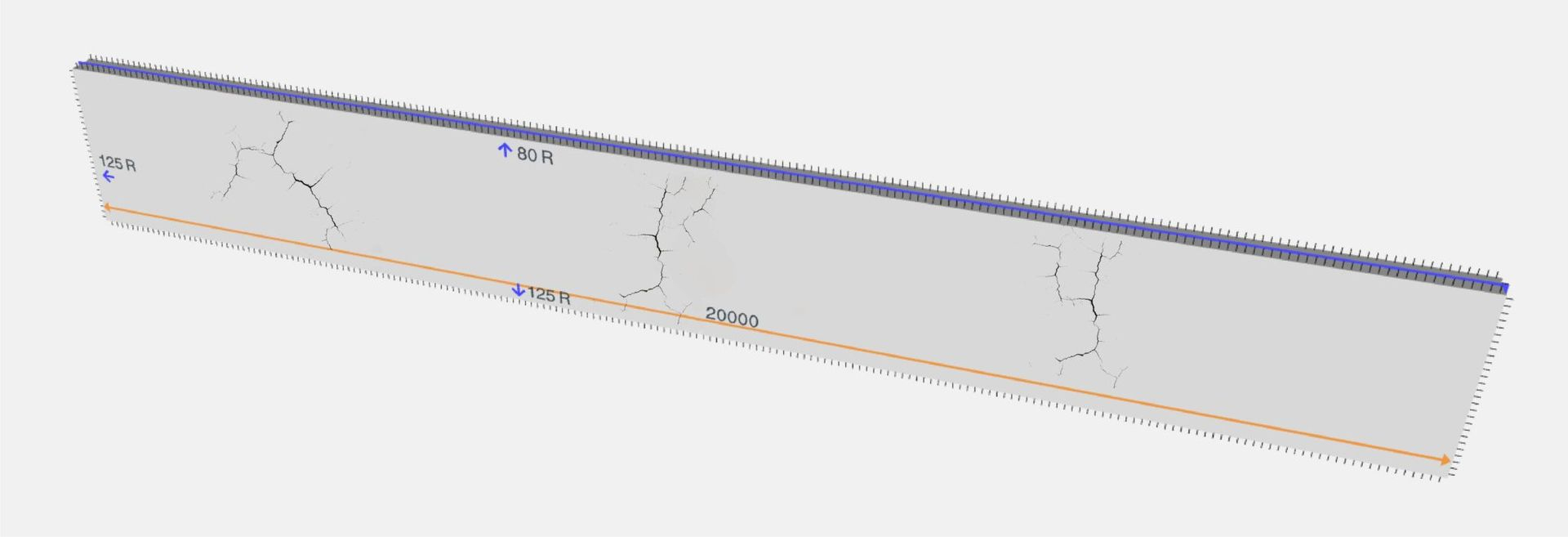

When casting 10m+ walls without WPM® Crack Inducing Waterstop then shrinkage cracks are guaranteed to occur!

With our experience from 2008, we have seen countless times the same problem!

Shrinkage cracks appear mostly after every 4-5m.

When using WPM®

Crack Inducing Waterstop

with calculated distance, we can solve shrinkage cracks problem!

As we saw that shrinkage cracks appear mostly after every 4-5m we decided to try different crack inducers on the market. Soon came out some of their deficits, and we decided to make our own crack inducer waterstop without the flaws.

In the picture, we can see how, on a 20m wall, we are using three WPM® Crack Inducing Waterstops with a 5m distance to control and guide shrinkage cracks while waterproofing them at the same time.

Result of the WPM® Crack Inducing Waterstop - Controlled and waterproofed shrinkage cracks.

Here is a price comparison using the classical i.e., "black tank" waterproofing method vs integral e.i. "white tank" waterproofing method on the same underground structure:

| With current prices (Estonia) | Waterproofing with the bituminous membrane (black tank method) | Waterproofing with crystalline admixture and WPM® waterstops (white tank method) |

| Foundation floor slab | 3200m2 x 35€ = 112 000€ | 1000m3 x 3kg = 3000kg x 6.90€ = 20 700€ |

| Walls | 1700m2 x 22€ = 37 400€ | 425m3 x 3kg = 1275kg x 6.90€ = 8 797.5€ |

| Intermediate ceiling (-1) | 3200m2 x 20€ = 64 000€ | 1000m3 x 3kg = 3000kg x 6.90€ = 20 700€ |

| Intermediate ceiling (0) | 3200m2 x 20€ = 64 000€ | 1000m3 x 3kg = 3000kg x 6.90€ = 20 700€ |

| WPM® Crack Inducing Waterstop | - | 660m x 51.50€ = 33 990€ |

| WPM® Waterstops | 500m x 10€ = 5000€ | 500m x 10€ = 5000€ |

| Reinforcement | 1000m x 10€ = 10 000€ | 1000m x 10€ = 10 000€ |

| SUM | 292 400€ | 119 887.5€ |

Save on metal

As steel prices have risen, we can use WPM® Crack Inducing Waterstop to use smaller diameter rebars in constructions that do not need over-dimensioning to control shrinkage cracks.

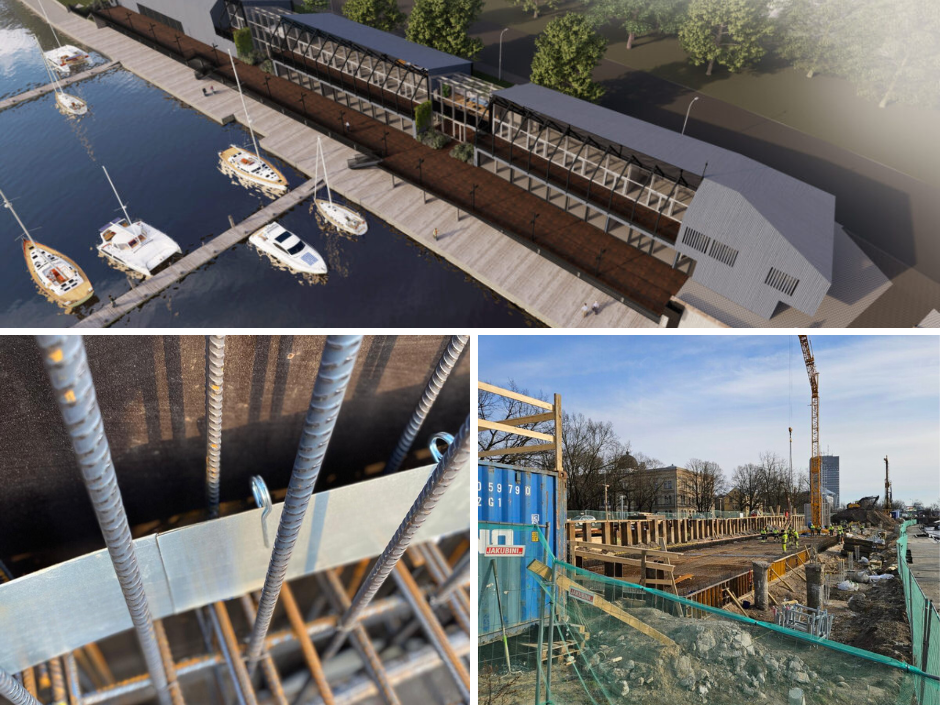

SELECTION OF PROJECTS

that has used a "White tank" waterproofing system

Sadama 4, Tallinn, ANKUR

- 1 floor underground

AS Merko Ehitus Eesti

- Concrete volume 1200 m³

Marijas 2a, Riga

- 2 floors underground

Novira Capital SIA

- Concrete volume 3800 m³

Järve 2, Tallinn, Järve torn

- 2 floors underground

TTP AS

- Concrete volume 3490 m³

Tērbatas 72, Riga

- 1 floor underground

YIT Latvija SIA

- Concrete volume 1169 m³

Eksporta 1A, Pētersala-Andrejsala, Riga

- 1 floor underground

PRO DEV SIA

- Concrete volume 1560 m³

Regati pst 3/4, 3/5, 3/6, 3/7, Pirita, Tallinn, Regati Homes(I stage)

- 1 floor underground

Liven AS

- Concrete volume

Rüpniecibas 27, Riga

- 1 floor underground

Merks SIA

- Concrete volume 2540 m³

Paldiski mnt 120, Pikaliiva Kaarmaja

- 1 floor underground

Bonava Eesti OÜ

- Concrete volume 3400 m³

Tērbatas iela 72, Riga, Latvia

What are YIT Latvia's thoughts about the "White Tank" solution in general?"We like that materials were easy to handle and install. The best part is that there was no pasting and plastering of anything, pure and quick work! The turnover time was faster than we were used to before which was just a bonus for us! "

Does YIT Latvija plan to continue using "White Tank" waterproofing solution in cooperation with Primostar SIA?

"When we can we definitely will! The solution is quick and easy and the Crack Inducers are genial for controlling shrinkage cracks!"

READ MORE ABOUT THE CUSTOMER STORY

WHAT WILL YOU GET

with our "white tank" waterproofing solution?

Reliable partner

Primostar was started in 2000 and has grown yearly turnover on average every year 26%

from 24 000€ to 1.4M € in 2021.

We have gone through economical crash of 2007-2008 and all other ressesions between and are stronger than ever!

Quality products

Primostar has been providing German quality materials since day one. We are working with industry-leading experts!

Now producing our own Estonian made product we are on par with the German quality if not even better!

20+ years of experience

By working closely with our partners we are seeing first hand what is working and what is not. With that, we have gathered knowledge of what is working and what is not, making us qualified to offer consultation with our experts for our products.

Indrek Uusalu

Primostar Group majority shareholder and CEO

Indrek is an entrepreneur, leader, product developer, and next-generation waterproofing solutions enthusiast.

He joined the company in 2002 as a commission-based salesman and became the CEO in 2003.

As a CEO, he is responsible for increasing the company's average turnover from 24 000€ to 1.4M€ in 2021.

Founded a manufacturing company, Primostar Tootmine OÜ, in 2018 with 16 years of knowledge in the industry and created a needed, patent-pending product to help builders waterproof their concrete structures better and smarter!

SOUNDS INTRIGUING?

Write to us, and let's see what we can do for your project!

,

,