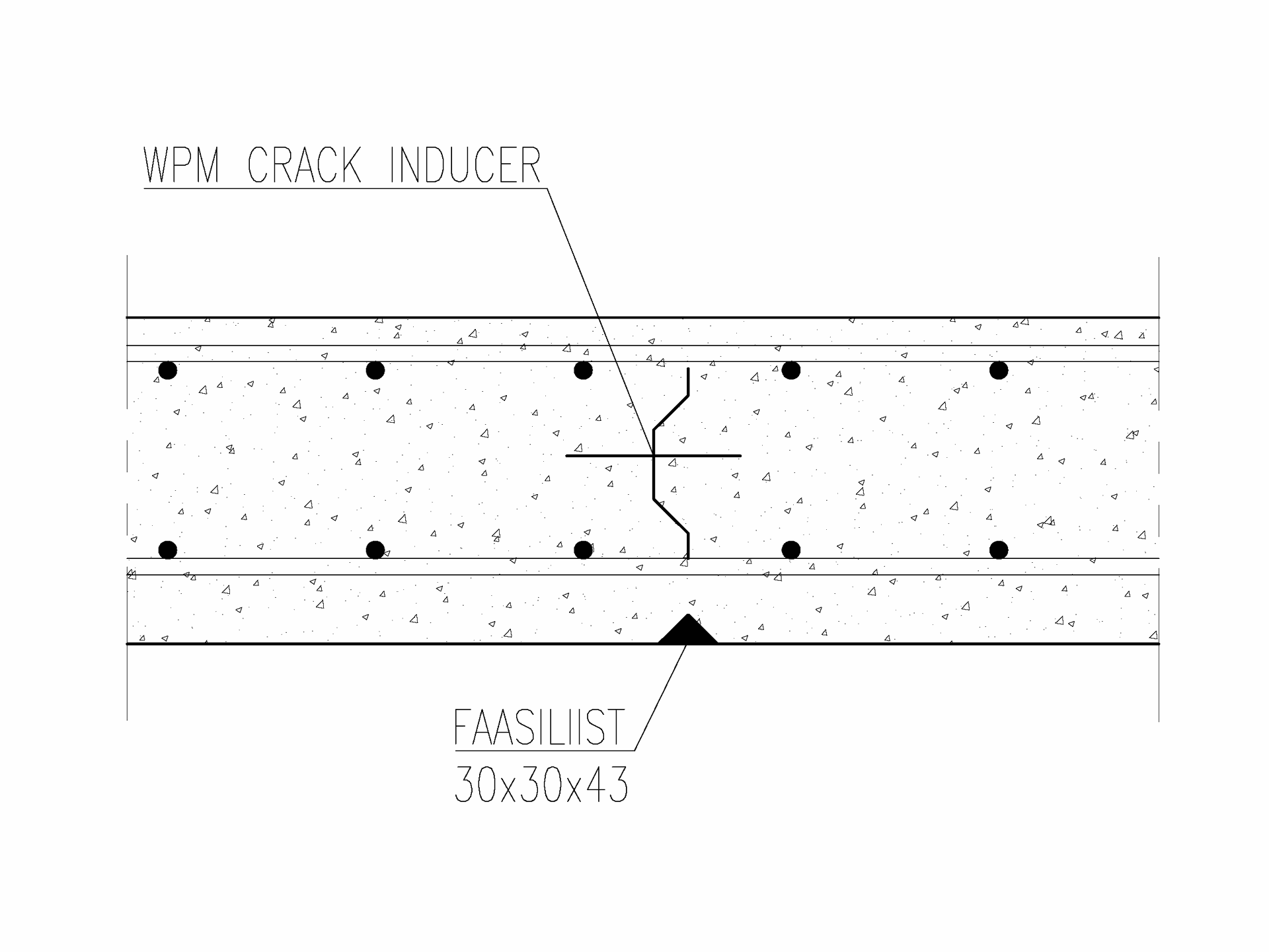

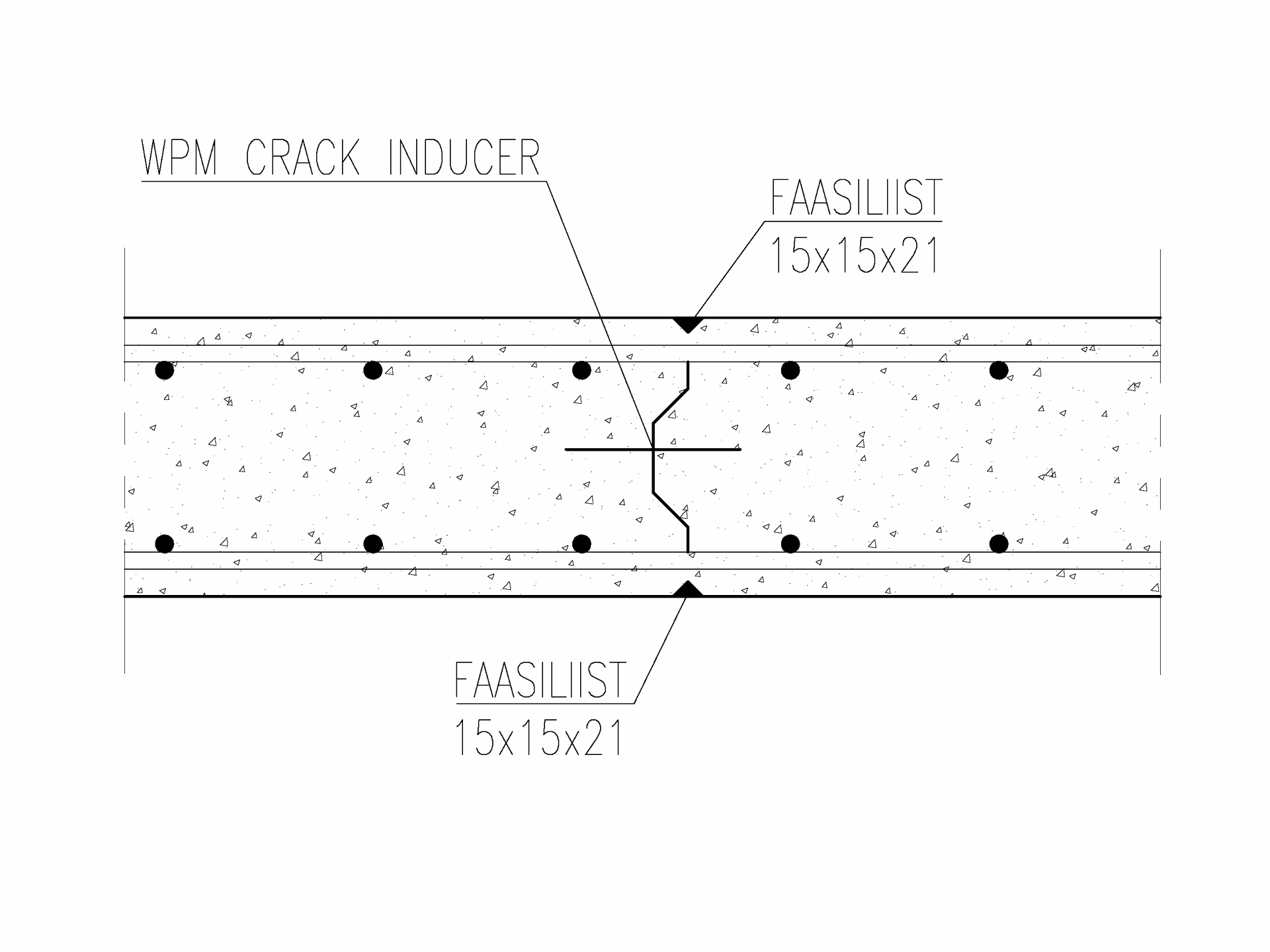

The innovative WPM® Crack Inducer, also known as the crack-inducing profile, is designed to control watertight shrinkage cracks in underground reinforced concrete structures. The crack-inducing profile does not weaken the structure and waterproofs the created crack. The Crack Inducer is used in walls, floor slabs, and intermediate floors.

This post will give you a brief overview of the WPM® Crack Inducer, from ordering to installation.

DECIDE ON THE IMPLEMENTATION

Before ordering, you need to know the volume of your underground concrete structure and choose whether you want to use it in the floor slab, wall, or both at the same time. In the case of a wall, you can use the 3D Crack Inducer calculator, which shows the installation locations of the crack-inducing profile and calculates the quantities for you. In addition to that, it will calculate chamfers and metal-sheet waterstop quantities. The calculator doesn't calculate crack inducers to floor slab or intermediate ceiling yet, but our Primostar team is here to help you.

WPM® Crack Inducer into the floor

WPM® Crack Inducer

into the wall

WPM® Crack Inducer

into partition ceilings

ORDER DELIVERY

We have WPM® Crack Inducers in stock, but if needed, we can manufacture them according to the project's specific requirements. Crack-inducing profiles are packed in a cardboard box with the necessary glues, clips, screws, and strips. You have to assemble the profile on the construction site yourself; however, by packaging in this way, we save on transport since all the necessary components are tightly packed.

Once the order is finished and our team has been notified, you will receive it within 1–3 working days, depending on the location. In Harjumaa, the delivery may already arrive within a couple of hours.

Our team is flexible and always ready to help. If the order is urgent, we will take this into account and will prioritize delivery to the courier, or if necessary, we will deliver it ourselves.

INSTALLATION

Installation methods vary for walls, intermediate ceilings, and floors. It is essential to follow the instructions provided by our expert team, who have extensive knowledge in this field.

The basic steps are straightforward. The WPM® Crack Inducers must be properly connected to each other. The profile ends have overlapping sections that should be secured with adhesive and either clips or screws to attach them to the adjacent profile. During installation, be attentive and careful to prevent any damage to the profiles. Additionally, ensure that the profiles are connected straight and securely to the rebars using binding wire. The installation of chamfer profiles must align with the plates, and remember that the installation method differs depending on whether the crack-inducing profile is in the wall or the floor. We recommend avoiding stepping on the profiles and minimizing excessive twisting, as these actions can affect their functionality within the structure.

CONCLUSION

Always remember to tailor your approach based on your specific project requirements. If you require assistance, don't hesitate to contact our experts. We are committed to supporting you throughout the process, and the sooner you involve us, the better solutions we can provide.

By following the simple installation basics and seeking our help when needed, you can navigate the installation journey with confidence. We are just a phone call away and always ready to assist you.