Tensions in the world have created a situation where the prices of various raw materials have started to rise gradually, reaching several times higher levels and making many products significantly more expensive for end consumers.

When the news has been more focused on the rise of fuel and electricity prices, the metal industry has also seen a significant increase in prices – for example, steel has risen by 242% compared to 2020 prices. The metal we use to make our profiles has increased by 190% over the same period. Although the situation is not good as the increase in raw material prices affects all costs, in our current situation, we see solutions to make the price of the metal in concrete works more affordable. .

In concrete work, the construction is dimensioned by using reinforcement so that when the concrete hardens, large shrinkage cracks in the structure do not occur, which later begin to seep water through. As a specialist in the waterproofing of concrete structures, we see the use of our construction joint and crack inducer profiles in combination with smaller diameter reinforcement as one way to reduce the price increase impact in concrete work.

Our profiles help to save the amount of metal used in concrete construction!

We can control and guide cracks during shrinkage using the WPM Crack Inducer profile. This means that we can utilize significantly less steel, which gives a significant victory in the construction price!

We have developed a 3D Automatic Crack Inducer Calculator, to show how closely the WPM CRACK INDUCER profiles must be installed for shrinkage cracks to occur where we want them to and be waterproof at the same time.

12mm rebars in a reinforced concrete wall without controlling the shrinkage cracks.

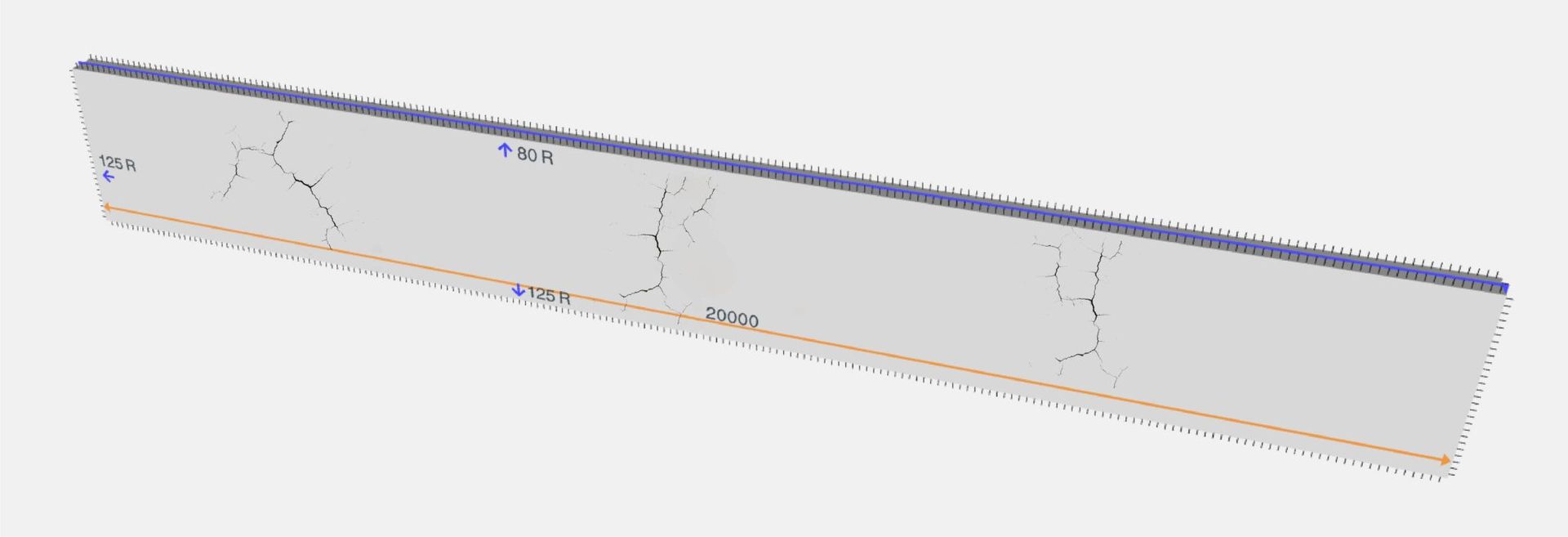

According to the information received from the builders we are working with, walls over 5 m are usually poured with the assumption that they do not crack, and if cracks occur, they are injected to stop the water from seeping. With that approach, builders dismiss the fact that concrete always shrinks in volume, so shrinkage cracks are inevitable and usually begin to leak water. The cost of injecting a leaking crack is 80-100€ a meeter. When casting a 20m wall all at once, at least six shrinkage cracks will appear on the wall’s surface, making the additional waterproofing cost a minimum of 500-600€.

12mm rebars in a reinforced concrete wall where shrinkage cracks are controlled with the WPM CRACK INDUCER profile.

Here is a 12 mm diameter reinforcement being used, which is over-dimensioned to prevent or reduce cracks due to shrinkage. However, based on real-life occasions, we can argue that even with an oversized 12 mm reinforcement, cracks appear in walls that are cast at once and are over 5 meters long. These cracks need to be injected later if the crack inducer profile is not used to control shrinkage cracks.

8mm rebars in a reinforced concrete wall where shrinkage cracks are controlled with the WPM CRACK INDUCER profile.

We know that a 4mm larger reinforcement in diameter does not control or directly reduce shrinkage cracks based on the previous examples. Therefore, it would be wise to replace expensive steel with galvanized sheet metal, which is more economical and prevents shrinkage cracks. By using galvanized sheet metal profiles in smaller increments, we can reduce the volume of the steel reinforcement to avoid possible oversizing and control shrinkage cracks effectively.

The following is an example of a calculation for a 2.7m x 16m wall using 8mm reinforcement and 2.7m x 20m using 12mm reinforcement with and without a crack inducer profile. We use walls of different sizes to show the maximum usability of the profiles with the given parameters.

We can see a cost comparison by the square meter when using 12 mm reinforcement and a smaller 8 mm reinforcement where the structural reinforcement is not over-dimensioned.

Calculation table

| Prices April 2022 | 12mm (150x150) reinforcement without checking for shrinkage cracks | 12mm (150x150) reinforcement + WPM CRACK INDUCER | 8mm (150x150) reinforcement + WPM CRACK INDUCER |

|---|---|---|---|

| Weight of 1 m2 reinforcementl | 12kg | 12kg | 5.4kg |

| Wall thickness 250mm | 12x2=24kg/m2 | 12x2=24kg/m2 | 5.4x2=10.8kg/m2 |

| Wall size | 2.7x20=54m2 | 2.7x20=54m2 | 2.7x16=43.2m2 |

| WPM CRACK INDUCER quantity cost | - | 20m kulub 3tk - 1tk=100€ | 16m kulub 3tk - 1tk=100€ |

| Price per m2 of WPM CRACK INDUCER | - | 300/(2.7x20)=5.5€/m2 | 300/(2.7x16)=6.9€/m2 |

| The price of 1 m2 of metal is 1.9 €/kg | 24x1.9=45.6€/m2 | 24x1.9=45.6€/m2 | 10.8x1.9=20.5€/m2 |

| 1m2 steel price | 45.6€ | 45.6+5.5=51.1€ | 20.5+6.9=27.4€ |

| Injection 100€/m | 6x100=600€ | 0€ | 0€ |

| TOTAL COST | 56.7€/m2 | 51.1€/m2 | 27.4€/m2 |

| SAVINGS | 0% | 9.9% | 51.7% |

Kokkuvõte

As can be seen from the calculation, it is possible to save more than 51% of the costs by not over-dimensioning the concrete reinforcement. If over-dimensioning is unnecessary, use the WPM CRACK INDUCER profile with 8 mm diameter reinforcement to control shrinkage cracks.

In a budget of 100 000€, this means saving 51 000€.

Therefore, if the steel price has exceeded the budget and there is no need to over-dimension the structure due to its load-bearing capacity, please get in touch with us, and we will find a reasonably priced solution for the project!