Environmentally friendly waterproofing solution for underground concrete construction

3 COMPONENT SOLUTION

to waterproof the underground reinforced concrete construction

WPM® Crack Inducing Waterstop

is used to control shrinkage cracks, which results in the planned shrinkage crack being immediately waterproof and in the desired location.

PATENTED PROFILE in USA, AÜE and ESTONIA

Made in Estonia

WPM® Metal Sheet Waterstop

used for waterproofing construction joints against pressurized water in various underground, reinforced concrete constructions.

WPM Metal Sheet Waterstop 80R / 125R / 125L

Made in Estonia

Crystalline waterproofing admixture

gives the concrete a self-healing ability. Together with the water entering the crack, the admixture can close the static cracks in the concrete with an opening width of less than 0.4 mm.

The main components are very common compounds in nature.

25

years in the market

7 198+

Crack Inducing Waterstop

amount (in meters)

74 940+

Metal Sheet Waterstop amount

(in meters)

388 969+

Crystalline waterproofing admixture amount (kg)

*Data are as of 2023.

SAVING

WITH THE WATERPROOFING PROCESS

ENVIRONMENT

You use 10 times less waterproofing material.

In order to be environmentally friendly, we have removed the packaging from the products.

TIME

Compared to conventional waterproofing, the installation of white tank waterproofing is up to 20 times faster.

The solution will last as long as the construction.

RESOURCE

You save on labor costs because any concrete worker can do the installation.

Installation does not require additional equipment or special technology.

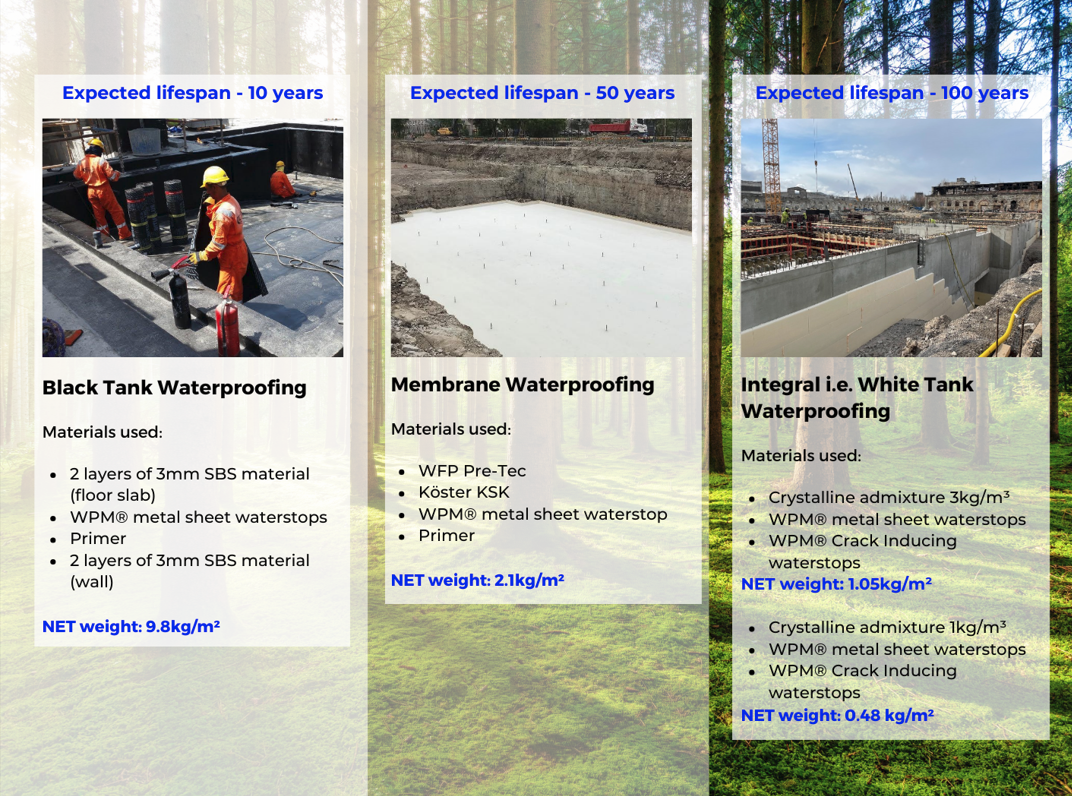

COMPARISON OF

WATERPROOFING SOLUTIONS

material consumption per m²

WHITE TANK SOLUTION

STEP-BY-STEP PROCESS OF WATERPROOFING

WPM® Crack Inducing Waterstop

It is added between the reinforcements before concrete casting to control shrinkage cracks and to waterproof the concrete structure.

WPM® Metal Sheet Waterstop

Construction joint profiles are added just before casting process to prevent water infiltration from the construction joints.

Crystalline admixture to concrete mix

Crystalline admixture is mixed to the concrete in the concrete factory. We use crystalline admixture in soluble bags so it can be inserted to the mix conveniently and with no waste.

Concrete casting

Concrete that is mixed with crystalline admixture is being pored after all the construction joint profiles and crack inducing profiles are installed.

Concrete structure is waterproof after casting proccess!

There is no need to add an additional membrane to the outer layer of the structure - unless the underground part is used as living quarters.

Additionally:

If there will be any cracks crystalline admixture in the concrete will grow it together (cracks up to 0.4mm)